Article de Alexandre SCHAMBERGER (MS EnvIM 2023-24)

Introduction

Electricity serves as an energy carrier, enabling the instant transmission of energy over long distances and its conversion into other forms, such as heat. This innovation revolutionized the energy supply sector in the late 19th century. Today, long-term projections for the global energy system indicate a significant rise in the importance of battery storage, especially electrochemical technologies, driven by several key factors. One major influence is the rapid growth of electric vehicles.

The International Energy Agency (IEA) predicts that by 2050, electric vehicles will dominate the light-duty vehicle market, leading to a substantial increase in battery demand. Additionally, the need for electricity storage is becoming increasingly important as the share of variable renewable energy sources continues to rise, the demand for system flexibility also increases, making batteries even more essential. Furthermore, the declining cost of battery packs is enabling electric vehicles to compete more effectively with traditional internal combustion engine vehicles.

Projections indicate a significant reduction in energy installation costs, from USD 150 to USD 1050 per kilowatt-hour (kWh) in 2016 to an estimated range of USD 75 to USD 480 per kWh by 2030, representing a decrease of 50% to 66% (International Renewable Energy Agency, 2017). Lastly, supportive policies and ambitious targets are further driving this transition. For example, the European Union’s commitment to achieving 100% zero-emission vehicle sales by 2035 provides clear guidance for car manufacturers and accelerates the adoption of battery technologies. (Passerini et al., 2024)

In parallel to this demand new materials and cutting-edge technologies are under development for a future sustainable battery. Before delving into emerging technologies, let’s examine the applications and limitations of the currently dominant lithium-ion battery.

The lithium Ion dominance

Considering the storage technologies, batteries stand out with their “response times”. This period refers to the speed at which a battery system switches between different operating modes. This feature defines the ability to quickly adapt to dynamic conditions such as rapid load changes or demand fluctuations.

Electrochemical batteries are ideally suited for electric vehicles (EVs) for several reasons. Their high energy density ensures that they are compact yet capable of storing a substantial amount of power, which is crucial for extending driving range without adding excessive weight. Their fast response time allows for smooth acceleration, providing a more enjoyable and efficient driving experience. Additionally, these batteries are easily rechargeable, making them practical for everyday use, and they incorporate safety features to prevent overheating and other issues.

Lithium-ion batteries have emerged as the dominant battery technology in both electric vehicles and stationary battery energy storage applications. They are far more energy dense (150-250 Wh/kg) than competing solutions such as lead acid (30-50 Wh/kg) or nickel cadmium batteries (50-75 Wh/kg). The names of these technologies indicate the specific metals or compounds used in the electrodes.

However, this technology also faces criticism. As an example, Tesla Model 3 holds an 80 kWh lithium-ion battery. CO2 emissions for manufacturing that battery would range between 2,4 and 16 metric tons. To give an order of magnitude, 1 ton of CO2 represents what a typical gas-powered car emits in about 4000 km of driving.(“How much CO2 is emitted by manufacturing batteries?”, 2024) Other limits of this technology are for example leakage risks and lithium deposits.

Furthermore, the projected rise in battery production leads to a strong increase in demand for critical minerals. Nevertheless, the field of electrochemical research holds vast potential to replace critical elements in current batteries with more abundant materials. This makes it unlikely that the development of this technology will be limited by geological constraints.

However, challenges arise from the geographic distribution and governance of these resources, particularly in regions where corruption is rampant and human rights protections are weak. For instance, cobalt extraction has garnered a negative reputation due to the prevalence of child labor in unregulated mines in the Congo. But as we will explore further, emerging battery technologies may enable the use of much less critical minerals while delivering even better performance.

Now, let’s explore the exciting advancements in battery technologies that promise to shape the future of the EV sector.

The future of batteries in the EV sector

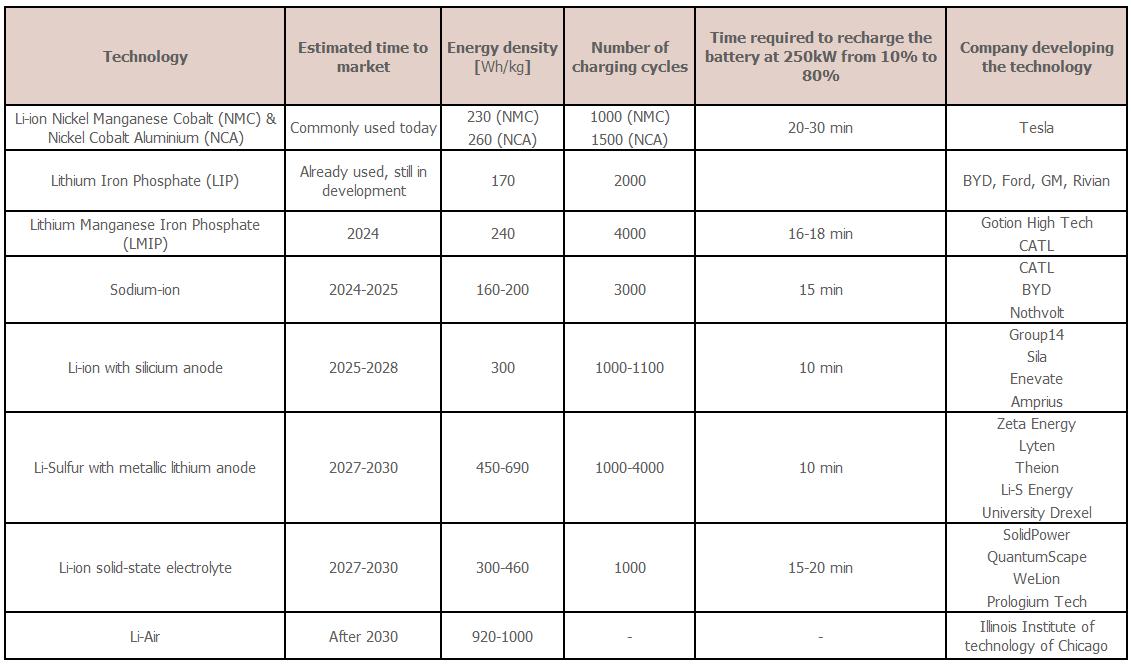

When comparing battery technologies, key characteristics to consider include energy density, which affects how much power the battery can hold relative to its size; the number of charging cycles, which indicates the battery’s longevity and how many times it can be charged and discharged before its performance diminishes; and the time required to recharge the battery to 80%, which impacts the convenience and efficiency of recharging. Table 1 below summarizes the performances of the new battery technologies.

Table 1 : Next Generation Battery Technologies and their performances compared to Li-ion (“Les technologies de batteries de 2024 à 2034 : une synthèse”, 2024)

In the following we will delve into the details of these technologies and their current limits.

LIP – LMIP Lithium Iron Phosphate battery

Lithium Iron Phosphate (LIP) batteries and Lithium Manganese Iron Phosphate (LMIP) batteries are two recent advancements in battery technology, designed to overcome some of the limitations of traditional lithium-ion (Li-ion) batteries.

LIP batteries, already widely used by Tesla and other manufacturers, offer an alternative to conventional Li-ion batteries by avoiding critical materials like nickel and cobalt, making them more affordable and ethically responsible. Although their energy density is lower, they are safer and have a longer lifespan. However, they are more sensitive to cold temperatures.

LMIP batteries improve energy density by incorporating manganese to the cathode, reaching up to 240 Wh/kg, surpassing NMC Li-ion batteries.(“Les technologies de batteries de 2024 à 2034 : une synthèse”, 2024)

These technologies still need to prove their effectiveness in cold temperatures and continue to evolve to maximize their energy density.

Sodium ion / Potassium ion battery

Sodium and Potassium-ion batteries offer significant advantages over traditional lithium-ion batteries. Firstly the abundance and the cost-effectiveness of the raw materials: Sodium-ion batteries do not need lithium, nickel, cobalt or graphite, all critical and expensive minerals, whereas there is 1000 times more Sodium than Lithium on earth and it can be found everywhere.(Langlois, 2022)

Secondly, the potential for higher energy density : research indicates that sodium and potassium batteries could achieve comparable or higher energy densities than lithium-ion batteries, particularly with advancements in electrode materials and electrolyte chemistry. For instance, the larger size of sodium and potassium ions helps to minimize dendrite formation.

Lithium-ion with silicium anode

Nearly all commercial lithium-ion batteries today use graphite as the anode material. Silicium can store 10 times more lithium ions than graphite. However, silicium crystals expand significantly (by nearly four times their volume) when filled with lithium ions during charging and shrink during discharging. The excessive stress caused by this expansion and contraction can degrade the anode, rendering it dysfunctional after just a few hundred cycles. Numerous research groups have worked hard to address this issue, achieving promising results.

Group14, a startup founded in 2015 in the US has succeeded in stabilizing silicon-rich anodes by encasing tiny silicon particles in porous hard carbon grains. The resulting composite powder is called SCC55™ (Silicon Carbon Composite). This powder offers a significant advantage in speeding up the development and commercialization of the technology, as it can be used in any proportion to replace traditional graphite powder without necessitating any modifications to existing battery cell manufacturing processes.

Lithium-Sulfur battery

In this technology, it is not lithium ion that move through the electrolyte but lithium polysulfides. These species move back and forth between a lithium metal anode and a sulfur catode. The use of sulfur, an abundant and cost-effective element, is the key to achieving energy densities higher than those of lithium-ion, because it can hold far more lithium ions than the metal oxides currently used. Furthermore, a lithium metal anode can also store significantly more lithium ions during charging compared to graphite.(Vedhanarayanan and Seetha Lakshmi, 2024)

The lithium-sulfur chemistry shows immense potential, but its practical realization faces significant challenges. One major obstacle is the “shuttle effect”, where sulfur tends to dissolve into intermediate polysulfide species, leading to the loss of active material, reduced cycle life, and overall degradation of performance.

However, advances in electrolyte chemistry, such as the use of high-concentration electrolytes, functional additives, and protective coatings have been shown to successfully suppress polysulfide dissolution, resulting in enhanced overall electrochemical performance of Li-S batteries. These advancements highlight a promising future for lithium-sulfur chemistry, with companies like Zeta Energy leading its development.

Solid-state Li-ion

The liquid electrolytes designs, although effective, pose 2 problems: leakage risks and lithium deposits called dendrites that may induce a short circuit in the battery and therefore increases flammability. While these issues can be addressed with additional materials, doing so increases the battery’s weight, thereby lowering its energy density.

The solid-state battery design seeks to eliminate these risks by replacing the liquid electrolyte with a solid electrolyte. The shift towards solid-state batteries brings about significant improvements in terms of safety. By eliminating flammable liquid electrolytes, solid-state batteries reduce the risk of thermal runaway, making them inherently safer. Additionally, solid electrolytes are more robust, contributing to longer battery life and addressing concerns about degradation and capacity fade often encountered in traditional lithium-ion batteries over time.(Vedhanarayanan and Seetha Lakshmi, 2024) Apart from being safer, solid-state batteries also have the potential for significantly higher energy density.

Despite the promising potential of solid-state batteries, there are still challenges that need to be overcome in order for them to be widely adopted. The manufacturing of scalable solid-state batteries at a competitive cost is an obstacle that researchers and engineers are actively addressing. Another challenge is related to the interface between solid electrolytes and electrode materials, as well as the mechanical stresses that occur during charge-discharge cycles.

Li-air: the future ?

A lithium-air battery uses a lithium metal anode and a specially designed cathode that reacts with oxygen from the air during discharge. Larry A. Curtiss and Mohammad Asadi from the Illinois Institute of Technology are the pioneers of this technology (“A room temperature rechargeable Li2O-based lithium-air battery enabled by a solid electrolyte”, 2023).

This type of battery can be up to four times lighter than today’s lithium-ion batteries because lithium is much lighter than the graphite typically used in anodes, and lithium oxide, formed in the reaction, is much lighter than the oxides used in conventional NMC batteries. Additionally, each lithium atom in the anode can store more lithium ions during charging than the carbon atoms in graphite, and the energy is stored in strong bonds in the lithium oxide at the cathode.

However, past prototypes struggled with issues like excessive heat loss, limited recharge cycles, and low power output. The recent breakthrough came from developing a new solid electrolyte, a ceramic-polymer composite that conducts lithium ions 15 times better than previous versions, and a more efficient catalyst in the cathode, addressing these challenges. Further improvement are needed to make this technology scalable and economically viable (Karunarathne et al., 2024).

There are still significant challenges to overcome, explaining the different estimated time to market ranging from 2024 to after 2030 of these technologies (see Table 1). Necessitating collaborative efforts from researchers, industries, and policymakers.

The global race for battery leadership

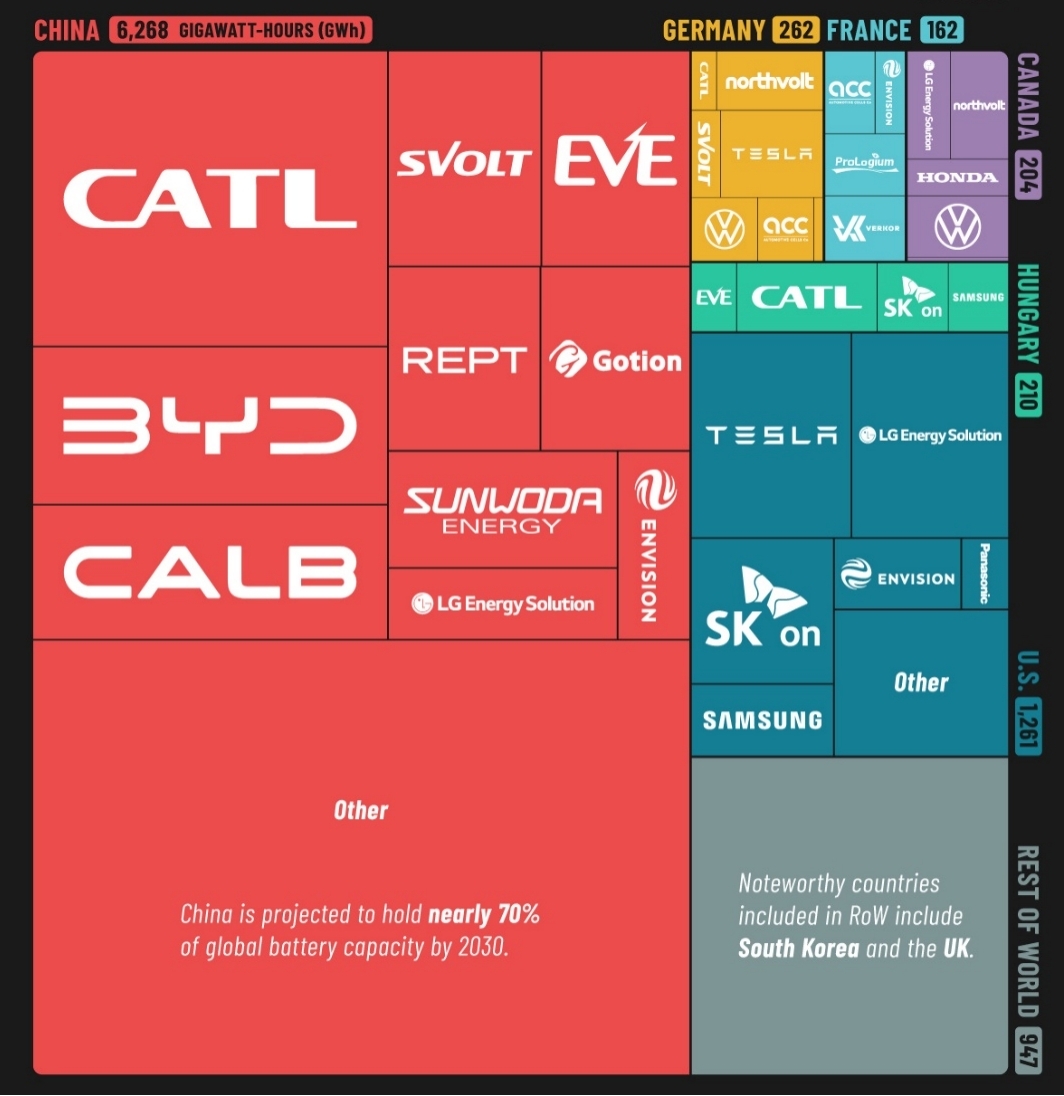

The global battery industry is experiencing rapid growth, with China leading in production and innovation. Chinese companies like CATL and BYD dominate the market, collectively holding nearly 70% of global production as of September 2024 (see Figure 1). This dominance is bolstered by substantial investments in research and development, enabling advancements in battery technologies.

Figure 1 : Top 6 Lithium-Ion Battery Capacity by 2030 (source: Benchmark Mineral Intelligence) (“The top lithium-ion battery producing countries by 2030”, 2024)

The US is intensifying efforts to expand its battery manufacturing capabilities. Companies like Tesla are investing in gigafactories to boost production and drive innovation in battery technologies (“Tesla’s EV battery production and global gigafactory network”, 2024). Additionally, U.S. firms are focusing on developing advanced battery chemistries and solid-state technologies to remain competitive (Donnelly, 2022).

Japan and South Korea continue to be key players in battery innovation, with companies such as Panasonic and LG Chem investing in research to improve battery performance and safety. (“Global battery race”, 2024)

In Europe, Poland and Hungary are significant battery producers, accounting for approximately 60% and 30% of the region’s output, respectively, in 2023. Germany leads in electric vehicle (EV) production, contributing nearly 50% of European EV manufacturing (“Trends in electric vehicle batteries”, 2024). Europe is rapidly expanding its battery production capabilities through the establishment of numerous gigafactories, aiming at reducing reliance on imports from China and the US.

To catch up with Asia, US and European companies are also exploring new business models and sustainable production processes to enhance their position in the battery value chain (“Lithium-ion battery demand forecast for 2030 | McKinsey”, 2023) (“Battery Monitor 2022”, 2023).

Conclusion

An important aspect of these new sustainable business models is for example the extended life cycle of batteries. The increasing use of batteries worldwide will result in a significant accumulation of end-of-life (EoL) and Waste Electrical and Electronic Equipment (WEEE), which require effective management to avoid environmental hazards. Watt4ever is an example of company specialized in extending the life cycle of batteries by remanufacturing and reusing them.

Overall, the global battery landscape is characterized by a dynamic interplay of production capacity and technological innovation, with various countries striving to enhance their roles in this critical sector. The potential of next-generation batteries extends beyond scientific inquiry : it offers a pathway to a sustainable, efficient, and resilient energy future.

A room temperature rechargeable Li2O-based lithium-air battery enabled by a solid electrolyte [WWW Document], 2023. https://doi.org/10.1126/science.abq1347

Battery Monitor 2022: Battery production and Product performance [WWW Document], 2023. . Roland Berg. URL https://www.rolandberger.com/en/Insights/Publications/Battery-Monitor-2022-Battery-production-and-Product-performance.html (accessed 11.21.24).

Donnelly, B., 2022. The global race for battery production is underway [WWW Document]. Tech Brew. URL https://www.emergingtechbrew.com/stories/2022/01/28/the-global-race-for-battery-production-is-underway (accessed 11.21.24).

Global battery race: 800% surge in production, 90% drop in price, know the leaders and laggards | Special-reports – Gulf News [WWW Document], 2024. URL https://gulfnews.com/special-reports/global-battery-race-800-surge-in-production-90-drop-in-price-know-the-leaders-and-laggards-1.1726222194649?utm_source=chatgpt.com (accessed 11.21.24).

How much CO2 is emitted by manufacturing batteries? | MIT Climate Portal [WWW Document], n.d. URL https://climate.mit.edu/ask-mit/how-much-co2-emitted-manufacturing-batteries (accessed 5.5.24).

International Renewable Energy Agency, 2017. Electricity storage and renewables: Costs and markets to 2030.

Karunarathne, S., Malaarachchi, C.K., Abdelkader, A.M., Kamali, A.R., 2024. Advances in bifunctional electrocatalysts towards high-performing Li-air batteries. J. Power Sources 607, 234553. https://doi.org/10.1016/j.jpowsour.2024.234553

Langlois, P., 2022. Les nouvelles batteries sodium-ion sans nickel, cobalt, lithium, graphite ni cuivre [WWW Document]. Roulez Électr. – Votre Réf. En Électromobilité Au Qué. URL https://roulezelectrique.com/les-nouvelles-batteries-sodium-ion-sans-nickel-cobalt-lithium-graphite-ni-cuivre/ (accessed 11.20.24).

Les technologies de batteries de 2024 à 2034 : une synthèse | Roulez Électrique – Votre référence en électromobilité au Québec [WWW Document], n.d. URL https://roulezelectrique.com/les-technologies-de-batteries-de-2024-a-2034-une-synthese/ (accessed 8.11.24).

Lithium-ion battery demand forecast for 2030 | McKinsey [WWW Document], n.d. URL https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/battery-2030-resilient-sustainable-and-circular?utm_source=chatgpt.com (accessed 11.21.24).

Passerini, S., Barelli, L., Baumann, M., n.d. Technologies to Boost the Clean Energy Transition Cost, Sustainability, and Performance Analysis.

Tesla’s EV battery production and global gigafactory network | Article | Automotive Manufacturing Solutions [WWW Document], n.d. URL https://www.automotivemanufacturingsolutions.com/ev-battery-production/teslas-ev-battery-production-and-global-gigafactory-network/45873.article?utm_source=chatgpt.com (accessed 11.21.24).

The top lithium-ion battery producing countries by 2030 | EVBoosters [WWW Document], n.d. . https://evboosters.com/. URL https://evboosters.com/ev-charging-news/the-top-lithium-ion-battery-producing-countries-by-2030/ (accessed 11.21.24).

Trends in electric vehicle batteries – Global EV Outlook 2024 – Analysis [WWW Document], n.d. . IEA. URL https://www.iea.org/reports/global-ev-outlook-2024/trends-in-electric-vehicle-batteries (accessed 11.21.24).

Vedhanarayanan, B., Seetha Lakshmi, K.C., 2024. Beyond lithium-ion: emerging frontiers in next-generation battery technologies. Front. Batter. Electrochem. 3. https://doi.org/10.3389/fbael.2024.1377192